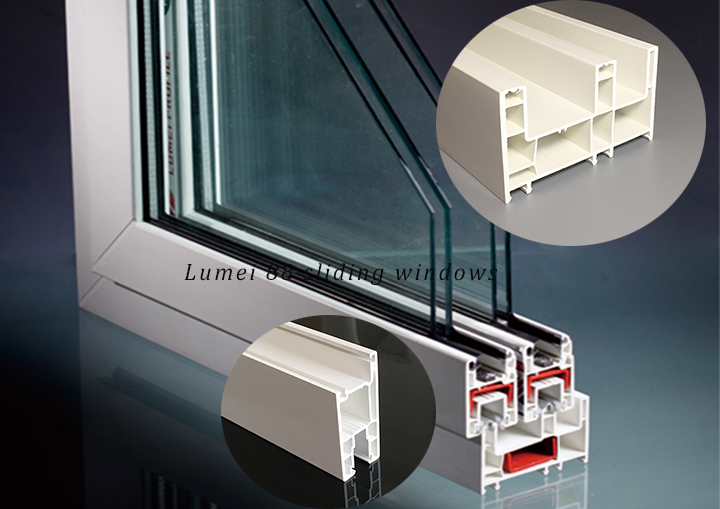

Pvc Sliding Doors Profiles with laminated wooden color

Basic Info

Model No.: LMTL-80

Product Description

80 european style sliding series is different from traditional 80 series with independent drainage chamber and three chambers, used for 80 sliding windows and doors. matched with screen sash profile, the added top groove makes the sealing more superior than the general sliding window. High-end sash profiles can be used to make the sliding window with the choice of actuator. Perfectly matched with the 60 series, it makes the selection of plastic doors and windows more convenient and suitable.

| Product Name | pvc sliding doors profiles |

| Material | 1.80mm pvc sliding doors profiles |

| 2. wooden laminated color | |

| 3. sliding doors | |

| 4. Strong reinforcement steel | |

| 5. Rubber strip | |

| 6. Hair strip | |

| 7. Air bubble polysheet, card paper, wooden box for packaging as requested | |

| Specification & Features | 1. Excellent heat preservation performance |

| 2. Good sound insulation performance | |

| 3. Anti-aging | |

| 4. Good combustion-retarding performance | |

| 5. Resist impacts | |

| 6. Good waterproof performance | |

| 7. Good anti-theft | |

| 8. Easy maintenance | |

| 9. Good air tightness | |

| Product Design | 1. Designing based on customer's requirement; |

| 2. Designing based on our technical knowledge; | |

| 3. Improving based on customer's design with our profession | |

| 4. Totally follow customer's original design. | |

| Color | White |

| Full color | |

| MC Co-extruded on white | |

| MC Co-extruded on full color with wooden color | |

| Film coated on white with wooden color | |

| Film coated on full color and wooden color | |

| Processing | 1.Profile culculating and Cutting |

| 2.Drilling holes for hardware, drainage | |

| 3.Fixing reinforcement steel | |

| 4.Welding shape and cleaning | |

| 5. Applying rubber and hair strip | |

| 6. Installing hardware and glass | |

| 7. Packing | |

| Certification | ISO9001, CE |

| Use | Both interior and exterior for all kinds of constructions,can be assembled into different window types to fit for different building style. |

| MOQ | 10 tons |

| Production capacity | 80000tons/year |

| Lead time | About 20 days after receipt of 30% advanced payment |

| Price term | FOB qingdao |

| Payment term | T/T 30% in advance, the balance before shipment |

Technological Process :

| Blending mixed power The material is top quality blending of plyvinyl chloride (PVC) and the stabilizer,lubricant,processing improver ,aging agent and colorant. | |

| Cone screwed tube extrusion The mixed power was compressed to shape by the cone screwed tune and the mould. | |

| Finalizing the shape The pariso is designed by the mould of designing in the vacuum cooling device. | |

| Traction Setting and regulating the speed of traction according to the speed of extrusion. | |

| Cutting The product is cut according to the required length and the protective film is pasted. | |

| Inspecting Each blade of our PVC profiles strictly inspected .Your satisfaction is our biggest wish. | |

| Packing PVC profile is packed by plastic film.It is suitable for long-distance sea delivery. | |

| Loading Container We have professional team and experienced experts,which can guarantee the cargo and the container be firm and safe.Our pvc profiles can reach to every port of the world safe and sound. | |

Product Categories : Plastic Extrusion > PVC Profile Extrusion